I wanted to explore the traditional techniques and processes involved in book binding to see if I can apply any techniques to my own work. this is because I would quite like to accurately follow traditional techniques where I can in order to maintain this old craft. I have found through this research I already undertake some of the traditional techniques but Iam keen to explore forwarding, gilding and using a sewing frame (although it is unlikely I will be able to use this)

According to bookbinding.co.uk the hand bookbinding process has not changed over centuries. The image Traditional craftsmanship as shown in the image below (of a french binary between 1951-1956, image from Diderot Encyclopédie)

Bookbinding.co.uk. 2020. Tradition. [online] Available at: <http://www.bookbinding.co.uk/tradition.htm> [Accessed 11 May 2020].

Bookbinding.co.uk. 2020. Tradition. [online] Available at: <http://www.bookbinding.co.uk/tradition.htm> [Accessed 11 May 2020].

The traditional Equipment shown in the image is still used today by binders, although manufactured mass produced books use a different process that is mainly run by machines. The image shows a press, a sewing frame, a plough, chopper and a finishing press.

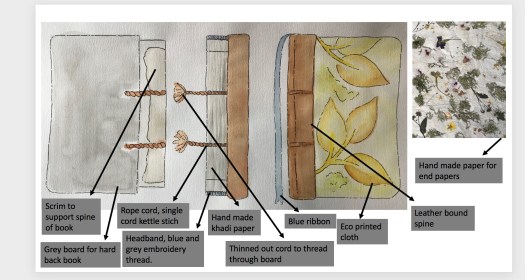

Traditionally the books are bound by folding the sheets into signatures which are then bound together using thread and cord in the sewing frame.

End papers have a decorative roll in the book binding process. these traditionally are marbled or screen printed.

In the image below (Headbanding – S&S Bindery Poland St circa 1945) the ladies are making headbands. Headbands are made by sewing silk threads into the top of the book traditionally using leather cord. these can become very complex and intricate. they also protect the tops and bottoms of the books when held in a book shelf and pulled out.

Bookbinding.co.uk. 2020. Tradition. [online] Available at: <http://www.bookbinding.co.uk/tradition.htm> [Accessed 11 May 2020].

The image shows a man gilding a book ( S&S workshop- gilding department 2004). The edges of books are traditionally gilded with gold. the bookblock is cut on a plough or by hand to smooth the edges and make the pages flush, This is then sanded by hand, then gold leaf is applied to the edges then polished using a agate burnisher.

Bookbinding.co.uk. 2020. Tradition. [online] Available at: <http://www.bookbinding.co.uk/tradition.htm> [Accessed 11 May 2020].

The boards for hardback books use mill board traditionally, this is cut by hand on a board chopper and then sanded till smooth. the boards are then attached to the board by the process of lacing-in. holes are pressed into the board using an awl and the cord threaded through. this helps the strength and means when the leather frails the book binding will stay together.

Forwarding is a process that is used to round the edges of the spine. the book block is held in a press and the book is gently hammered by “Rounding and Backing”. This process strengthens the spine as hammering it allows the sections to fold into each other.

Goatskin and calfskin make the best binding leather. calfskin is more traditionally used in french and English binding and is dyed using vegetables.

Finishing the books is traditionally done using decorative brass tools. they are pressed into the surface to create an indent and the 22 Carat gold leaf is then applied using egg glaire. The tool is then heated up again to fuse the egg and the gold to the leather. this technique is extremely advanced and can take years to master.

According to Khadipapers.com (Khadi Papers. 2020. About The Paper – Khadi Papers. [online] Available at: <

According to Khadipapers.com (Khadi Papers. 2020. About The Paper – Khadi Papers. [online] Available at: <

Bookbinding.co.uk. 2020. Tradition. [online] Available at: <

Bookbinding.co.uk. 2020. Tradition. [online] Available at: <