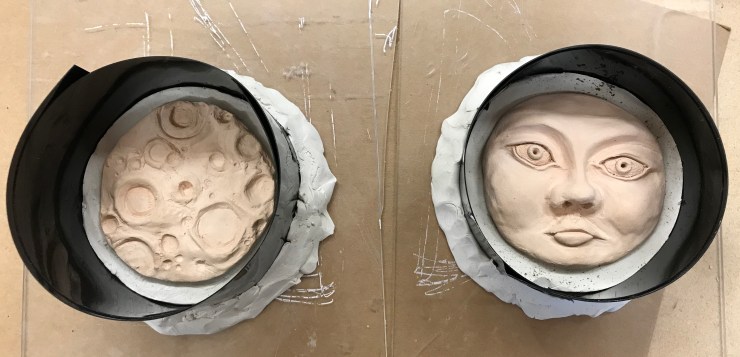

Using plasticine I fixed my forms to the board reinforcing the edges with plastic and tape to form the area for the silicone mould. after mixing the ingredients, I poured it into the moulds and released as many of the air bubbles I could as this affects the detailed, i let the moulds set overnight.

LESSON LEARNED! use a release agent on the ceramics before covering in silicone, when taking these from the mould the silicone stuck to the forms and I lost a lot of details that I will have to rebuild using wax.

Using these moulds I then melted green wax and cast the forms. As I made these as two separate forms I then had to melt the two halves together in order to make the medal whole. I am pleased with the overall outcome. I now have to wait until my group is all at the same stage so that we can progress onto the ceramic tree stage of the bronze process.